What is FIBC?

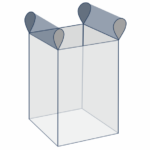

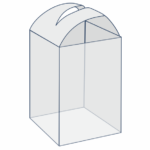

Flexible Intermediate Bulk Container (FIBC), bulk bags, jumbo bags or simply big bags are large dimension standardized containers for storing, transporting, and handling dry, granular products and/or slurry material. FIBCs are amongst the most economical bags and ideal types of packaging for shipping and storing dry bulk products. They can be produced from either tubular or flat polypropylene (PP Woven fabrics) These fabrics can be either coated or uncoated and vary in weights depending on the requirements of the Safe Working Load (SWL) or Safety Factor.

These bags can come in various shapes and sizes and are tailored to suit specific customer requirements. Safe working loads from 500kg through to 3000kg can be achieved and bags can be sold as either single trip (designed to be filled once only) or as a multiple use item. All bulk bags are manufactured under the ISO-9000 quality system which give our customers the confidence that they are buying a quality product that will not fail them.

We only procure our bags from reputable manufacturers and those that we do use would be classed as World leaders in this area. Suman Exim can supply bags rated for Dangerous Goods handling which we do on a regular basis. Dangerous Goods bulk bags require a more stringent testing regime. Food grade bags is another area we cover and our manufacturers currently hold ISO 9001:2015 & FSSC 22000 SIO 9001-2015, FSSC22000 & BRC certification giving our customers confidence that the bags will be free of contamination and that their product’s integrity will be maintained

Why Choose FIBC Bag ?

- The use of warehouse space as can be folded flat to take up a fraction of the space required for other industrial packages.

- Can be used for hazardous chemicals as specified in the UN Chapter 65 ecommendations.

- Can be handled, transported and stored without pallets due to integrated lifting loops.

- Woven polypropylene properties (PP) allow easy product information printing on bags.

- Supplied in a variety of dimensions and filling, discharging and lifting facilities.

- Tailor-made and can be customized as per the manufacturing process.

- Strong yet flexible and offers a low unit cost.

- Can carry up to 1000 times its own weight.

- Polypropylene bulk bags are cost-effective.

- Does not require further packaging.

- Can lift from 500-2000 kg.

- EFIBCA standards.

Industry segments where FIBCs are widely used:

- Pharma Industries

- Foods Products

- Seeds & Grains

- Constructions

- Agriculture

- Refectories

- Fiberglass

- Chemicals

- Pigments

- Fertilizer

- Minning

- Plastics

Types of FIBCs

At Suman Exim, we understand your packaging needs and specialize in three specific types of FIBC bags universally labeled as Type A, B or C. If you are interested in these products, we welcome you to examine the elements involved in the selection of an appropriate type of bag. It is important to assess the dangers involved in the handling of hazardous products. Our technical services team will be glad to assist you through this process.

Type A bulk bags

- Static electricity is generated when the product moves against the surface of the bag while being filled or emptied.

- Shouldn’t be used for carrying inflammable materials or kept near a potentially combustible environment.

- Type A FIBCs are made of plain-woven polypropylene and other non-conductive fabrics.

- No static protection provided by Type A FIBCs.

- Can transport non-combustible products safely.

The don't of type A Bulk Bags

- Don’t use near a flammable atmosphere with minimum ignition energy < 1,000mJ present.

- Don’t let flammable solvents or gases accumulate around Type A FIBC.

- Don’t transport flammable products.

Type B bulk bags

Type A & Type B FIBCS are quite similar in some aspects. Let’s take a look at them.

- Also made of plain-woven polypropylene fabrics or other non-conductive material.

- Also do not possess any mechanism for dissipating static electricity.While the bases are similar, Type B FIBC should be handled with more care to ensure your safety. Let’s take a look into a few of them.

- Unlike Type A FIBCs, Type B is made from materials that have a low breakdown voltage to prevent an incident where highly energetic, and dangerous propagating brush discharges occur.

- Low breakdown voltage (less than 4KV) to prevent propagating brush discharges (PBD).

- Although they can prevent propagating brush discharges, they are not considered anti-static bulk bags because they do not dispel an electrostatic charge.

- Can be used in the presence of the minor combustible dust with MIE more than 3mj; provided flammable vapours of gases are absent.

- Can transport dry and flammable powders.

The don't of type B Bulk Bags

- Don’t use in environments with dust and ignition energies more than 3mJ.

- Don’t let flammable solvents or gases accumulate around Type B FIBC.

- Don’t transport flammable products

Type C bulk bags

If you are searching to fulfil Type C bulk bag needs, don’t forget to take a look at the pointers mentioned below to understand its specifications:

- Type C FIBCs or conductive FIBCs or ground-able FIBCs, are made from non-conductive polypropylene fabrics interwoven with conducting threads traditionally sewn in a grid pattern.

- Conducting threads must be electrically interconnected as well as connected to a designated ground/earth during filling and discharging.

- This connection to the ground/earth during filling and discharging is imperative to the safe use of Type C bulk bags.

- Flammable powders can be safely transported.

- Safe in the presence of flammable vapours, gases, dust or solvents around the bag.

The don't of type C Bulk Bags

- Don’t use when the ground connection is not present or has been damaged.

- Don’t use them if it shows resistance from any location FIBC to a ground-able point.